GPLA, in collaboration with DPR Construction, accelerated delivery of a 200MW AI-based data center in Midwest Texas using a design-build approach. By compressing structural steel design into five weeks and leveraging clustered teams and digital tools, GPLA enabled early steel delivery and maintained critical construction timelines. Their flexible, modular design and real-time coordination set a new benchmark for speed and precision in advanced tech construction, ensuring rapid market entry without compromising quality.

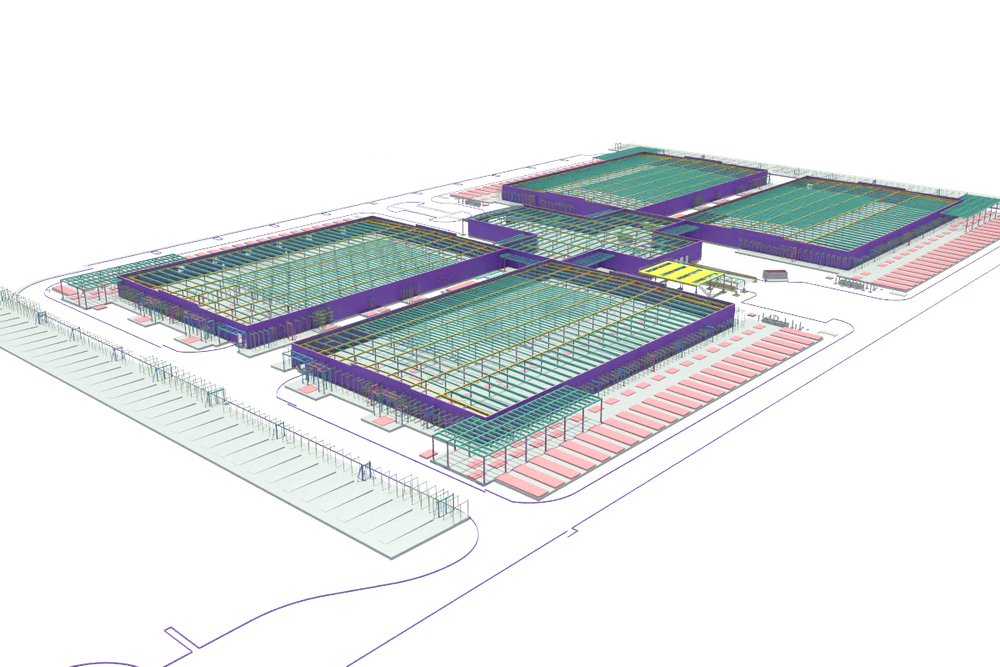

Crusoe Energy Abilene Data Center Campus

Abilene, Texas

GPLA'S Progressive Approach to Structural Design Speeds Up Schedule for AI Data Center

Accelerating Delivery

GPLA, working in tandem with general contractor DPR Construction, demonstrated speed and efficiency by utilizing a design-build framework for an advanced 200MW AI-based data center in Midwest Texas. Faced with an aggressive timeline, “GPLA compressed the structural steel design schedule from a six-to-eight-month process into five weeks,” states Josh Carney, President of GPLA.

This accomplishment highlights the power of integrated workflows where design, detailing, and shop drawings occur simultaneously, cutting months from the traditional process. This course of action expedited steel delivery to the site far ahead of conventional schedules, enabling construction to maintain its critical path and ensuring the client’s rapid market entry.

Key Milestones

Delivering initial structural designs for steel mill orders within two weeks (fabricated steel making it on-site within three months)

Completing fully detailed structural and fabrication models in under six weeks

This timeline was achieved through the “clustered team” methodology, where specialized groups focused on primary structures, secondary and support systems, and quality control while working concurrently. This system minimized rework and streamlined processes, setting a new industry benchmark for accelerated project delivery.

Working with a Collaborative Partner

The success of this project hinged on the seamless integration and collaboration between GPLA and DPR. From the outset, GPLA worked closely with DPR to align design decisions with construction needs. Real-time communication with field teams to evaluate the impact of design choices on construction speed, risk, and efficiency and leveraging advanced digital tools like Tekla enabled GPLA to produce highly detailed and fabrication-ready shop drawings. This eliminated the delays associated with traditional workflows. By aligning objectives and maintaining open lines of communication, GPLA and DPR ensured a cohesive plan that prioritized speed, quality, and adaptability.

Flexible Design Solutions

GPLA’s refined and adaptable design was critical to the project’s success. “Every piece of steel in this building was designed on the same dimensional grid, enabling interchangeability and streamlined construction.” Josh Carney, President of GPLA. The structural system incorporated prefabricated foundations and interchangeable steel components, ensuring flexibility to accommodate potential changes without compromising the schedule. The foundation design utilized pre-welded reinforcement cages with standardized dimensions, enabling rapid installation and real-time replacement of damaged pieces. By designing the building foundations with consistent elevations aligning to subgrade levels, GPLA eliminated the need for traditional concrete forms, reducing labor and material requirements.

Redefining Advanced Tech Constrction with Speed & Flexibility

GPLA’s expertise in complex structural analysis, prefabrication, and design build delivery is transforming speed-to-market within the advanced technology sector. By prioritizing speed, integration, and flexibility, GPLA successfully delivered a flexible structural design for an AI-based data center on an aggressive timeline without compromising quality. Our team showcased the value of collaboration, digital tools, and modular design in meeting the unique demands of advanced technology projects, offering a blueprint for success in high-speed, high-stakes construction.

"GPLA is one of the few structural engineering firms in the U.S. that designs structures using the same software that drives fabrication, enabling unmatched precision and speed."

Key Schedule

Highlights

GPLA efficiently transitioned from the design initiation phase to the release of the steel mill order in just two weeks.

GPLA compressed the total structural steel design and detailing schedule from a typical six-to-eight month process into just five weeks, covering the entire process from design initiation to the approval of steel shop drawings.

By implementing innovative and integrated engineering/detailing workflows along with efficient construction sequencing, the project timeline was reduced by 24 weeks from the critical path.