When Tesla was looking for a structural engineer that could think outside of the box and deliver innovative solutions, while also meeting a lightning-fast schedule, on its 5.4 million sq. ft. Gigafactory project in Sparks, NV – a massive new heavy manufacturing facility spanning the equivalent of about 100 football fields – they turned to GPLA to get the job done.

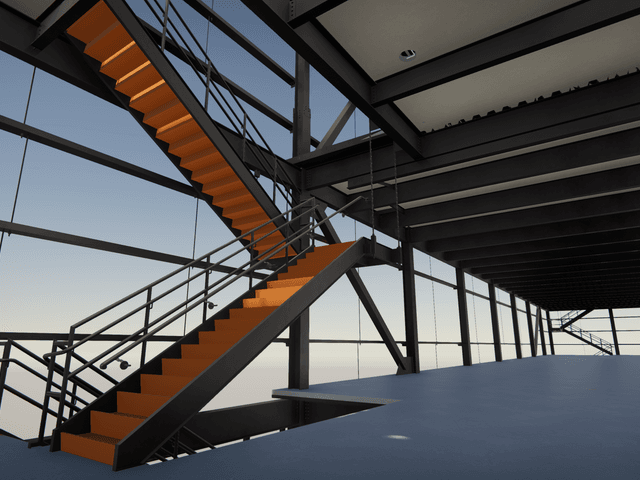

GPLA was brought on board the project as a consultant in 2015 to help devise an engineering solution that would efficiently add mezzanines into Buildings A, B, and C, which had already been designed by a different structural engineer. Tesla wanted to add the mezzanines in order to maximize the useable space in those buildings, which had a 70-ft. clear height. The Tesla construction manager who recommended bringing GPLA on board had worked with them on a previous project and knew they were creative engineers, adept at solving difficult engineering problems like this one.

GPLA came up with a solution to add approximately 372,000 sq. ft of mezzanines into the existing design of Buildings A, B, and C. Their solution saved schedule time as well, because it repurposed some of the framing components and the structural steel that was already sitting on the jobsite, originally slated for use in the next two buildings, for the mezzanine construction instead.

Seven Months from Mill Order to Topping Out

Following the success of GPLA’s initial work adding in the mezzanines, Tesla called them in the spring of 2016 and asked if they would take over as structural engineer of record on the rest of the Gigafactory project, as well as performing structural steel and rebar detailing work. There was one important caveat: it would have to be done at breakneck speed. Preorders for Tesla’s Model 3 had skyrocketed, and Tesla needed to move full steam ahead expanding its heavy manufacturing capacity in this critical new facility.

Again, GPLA delivered. Less than two weeks after the call from the owner that April, they had placed the first mill order, for Building F, with more to follow. This set the clock in motion for the building design and detailing to be completed by the time that steel reached the multiple fabrication facilities that were being used for this project. Seven months later, steel had topped out on all the buildings. And just 11 months after that first phone call, the team had designed and delivered to processing facilities some 3 million square feet of mostly ground-up structures for the D Quad and F Quad buildings.

GPLA engaged an outside consulting firm, Exponent, to assist with the high-end lateral analysis required for designing these unique structures, which had variable and evolving floor layouts depending on Tesla’s varying needs for the spaces. The team was able to accomplish the schedule by deploying GPLA’s HD BIM® approach. They built and maintained a single cloud-based Tekla Structures design model from which they directly produced the rebar and steel shop drawings, virtually eliminating structural RFIs and slashing months off the design-build schedule.

Innovative Design and Approaches

Subcontracted directly to GPLA, the steel detailers became an extension of the structural design team. The gravity and lateral designs were uncoupled by providing a 30-inch chase between gravity columns all around the buildings that were reserved for the lateral system. This allowed the gravity framing to be accelerated while the analysts at Exponent refined the lateral analysis and design.

Innovation was the hallmark of this project, with the most notable example being the innovative lateral system devised by the GPLA/Exponent team. To accommodate the design changes resulting from the constant evolution of the manufacturing processes, the team came up with a strongback concept that assured uniform yielding of the BRB system regardless of the mass distribution. The system was made reparable by providing true pins on the strongbacks that flanked a gravity column and Krawinkler fuses connecting the strongbacks to the gravity columns at the neutral axis of the composite truss system. All elements of the system were shop fabricated and field bolted.

Another innovation involved the stamping press pit, top-down construction that occurred in the final structure, Building G. GPLA developed a novel construction sequence that allowed the stamping press pit, which needed to be 40 ft. x 230 ft. x 19 ft.-6 inches in a 75-ft. bay, to be built after steel erection. The key was maintaining stability of the soils under the footing by excavating and building the top 10 feet first and then completing the excavation second. This allowed the rest of the process fit out to proceed in parallel with the pit construction.

Stamping Press Requires Unique Isolation System Design

GPLA/Exponent identified another potential problem, later validated with field testing, with vibrations from the planned stamping press interfering with sensitive manufacturing equipment in the adjacent building F. To mitigate the problem, the structural engineering team provided a solution in the form of a 30-inch thick, 40 ft. x 46 ft. concrete isolation base in the pit that supports the four concrete columns and the stamping press, a total of 800 tons, on 12 custom GERB dampers. This approach marked the first time this has been done in the U.S.